Industrial Chemicals

Leading Exporters, Wholesaler, Trader, Distributor and Importer of Aliphatic Blocked Polyisocyanate, Aliphatic Polyisocyanate HDI WB, Aromatic Polyisocyanate, Ethylene Imine Trifunctional Polyaziridine, Pentaerythritol Trifunctional Polyaziridine, Propylene Glycol, Propylene Imine Trifunctional Polyaziridine and Toluene Diisocyanate from Mumbai.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Application | water-reducible, lightfast one-component polyurethane baking coatings |

| Grade | Industrial Grade |

| Physical State | Liquid |

| Non-volatile Content | 39% |

| Viscosity | 99.9 |

| pH value at 20 DegreeC | 6.5 - 8.5 |

| NCO Content | 11.5 +- 0.5 |

Imprafix 2794 (39%) It is to increase the mechanical properties & chemical resistance of polyurethane-based textile coatings. It can be used for the formulation of water-reducible, lightfast one-component polyurethane baking coatings and as an additive in waterborne baking systems to improve flexibility, impact strength and adhesion.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Usage/application | Crosslinking Hydroxyl Functional Emulsions |

| Physical State | Liquid |

| Non-volatile Content | 39% |

| Viscosity | 99.9 |

| PH value at 20 DegreeC | 6.5 - 8.5 |

| NCO Content | 11.5 +- 0.5 |

Basonat HW 1180 PC, It exhibits excellent weather- & chemical resistance, and excellent adhesion to various substrates. It is low VOC crosslinker suitable for interior & exterior general industrial metal coating, plastic component coating, wood coatings for floor, furniture or millwork and automotive OEM or refinish applications.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Application | Industrial |

| Shelf Life | 1 Year |

| Color | Transparent |

| Purity | 100% |

| Form | Liquid |

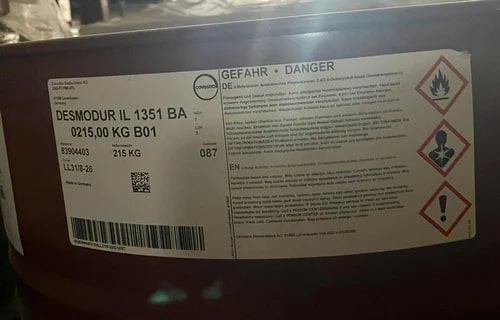

| Brand Name | Covestro |

| Density | 1.09 G/ML |

It is used as the hardener component for fast-drying two-pack polyurethane coatings for the furniture industry. Offers very short drying times and early sandability.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Application | Industrial |

| Purity | 100% |

| Form | Liquid |

| CAS No. | 52234-82-9 |

| Grade Standard | Industrial Grade |

| Formula | C21H35O6N3 |

| Density | 1.1+-0.1 |

| Flash Point | >110 |

HD 105, It Acts as a crosslinking agent and adhesion promoter. This product is high molecular tri-functional aziridine with carboxyl groups of acrylic emulsions and polyurethane dispersions forming a cross-linked network. Used in leather coating, textile coating, wood coatings, printing inks and overprint varnishes to improve wear, water, scuff, black heal, scuff and chemical resistance, shortens cure time, and promotes adhesion.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Application | printing inks, wood coatings, leather and textile coatings. |

| State | Liquid |

| Purity | 100% |

| Chemistry | C20H33N3O7 |

| Density | 1.158 |

| Flash Point | >110 |

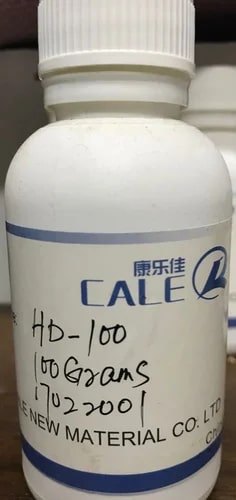

HD 100, It Acts as a crosslinking agent, adhesion promoter and modifier. Imparts strength, and flexibility, and improves solvent and alcohol and water resistance. It increases the hardness and upgrades adhesion to the difficult substrate. Improves adhesion to varied substrates, and increases scuff resistance and chemical resistance. Offers faster cure time. Also improves black heal resistance, abrasion resistance and wear resistance. Used in printing inks, wood coatings, leather and textile coatings.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Brand Name | BASF |

| Purity | 100% |

| Form | Liquid |

| Iodine Value | 2.5 Max |

| Water | 1 Max |

| pH | 4-6 |

It can be used in liquid hand soaps, lotions, creams and shampoos, as emulsifiers, pearlized, stabilizers, solubilizers & viscosity control agents. PEG (400) Monolaurate can be also used in the metalworking, pulp & paper, textile, household & institutional industries.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Brand Name | CALE |

| Purity | 100% |

| Usage/Application | Used as a cross-linker for both aqueous and non-aqueous coatings,inks,and adhesives,Printing Appl |

| Grade | Technical Grade |

| Density | 1.08 (g/ml @20 C) |

| Molecular Formula | C24H41O6N3,467.67 |

| Solubility | Inter Miscible with Water 11 |

| Boiling Point | -15/ Above 200 |

| Flash Point | 280 F (138 C) |

| Melting Point | -10 C (14 F ) |

| PH Value | 9.26 |

| Shelf Life | 1 Year |

| State of Matter | Liquid |

It is added to water based acrylic emulsions or polyurethane dispersions as a cross-linker for textile and leather coatings, industrial coatings, inks, adhesives and films to improve strength and flexibility, solvent resistance, alcohol and water resistance, hardness and adhesion to difficult substrates.

| Business Type | Exporter, Supplier, Trader, Importer |

| Country of Origin | India |

| Melting Point | 21.5 - 23.5 |

| Specific Gravity | 1.22 |

| Viscosity | at 100C cps - 0.70 |

| Boiling Point | 251 15 40 180 15 |

| Total Chlorine | 180 |

| Physical State | Liquid |

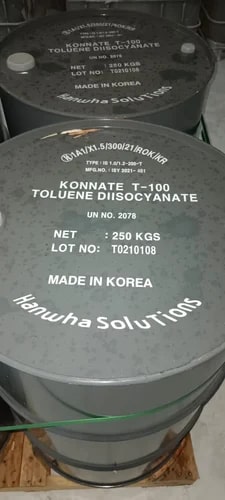

It is mainly used in the cast elastomers and the paint/coatings industries.